Our strength lies in our close partnership

with Chinese contract manufacturer.

We promise to provide the best products that meet customers' needs through repeated trials and close discussions with our quality-conscious Chinese contract manufacturer. In order to maintain the quality that meets customers' requirements, we have been visiting China since our inception to provide technical guidance in the manufacture and management of Japanese-quality magnets.

The trusting relationship and density of communication with the contract manufacturer are one of T.Technology's strengths and the source of our advanced technological capabilities and ability to offer solutions. Under our direction, all quality control from the manufacturing process to delivery is performed by T.Technology. We are committed to providing stable, high-quality products.

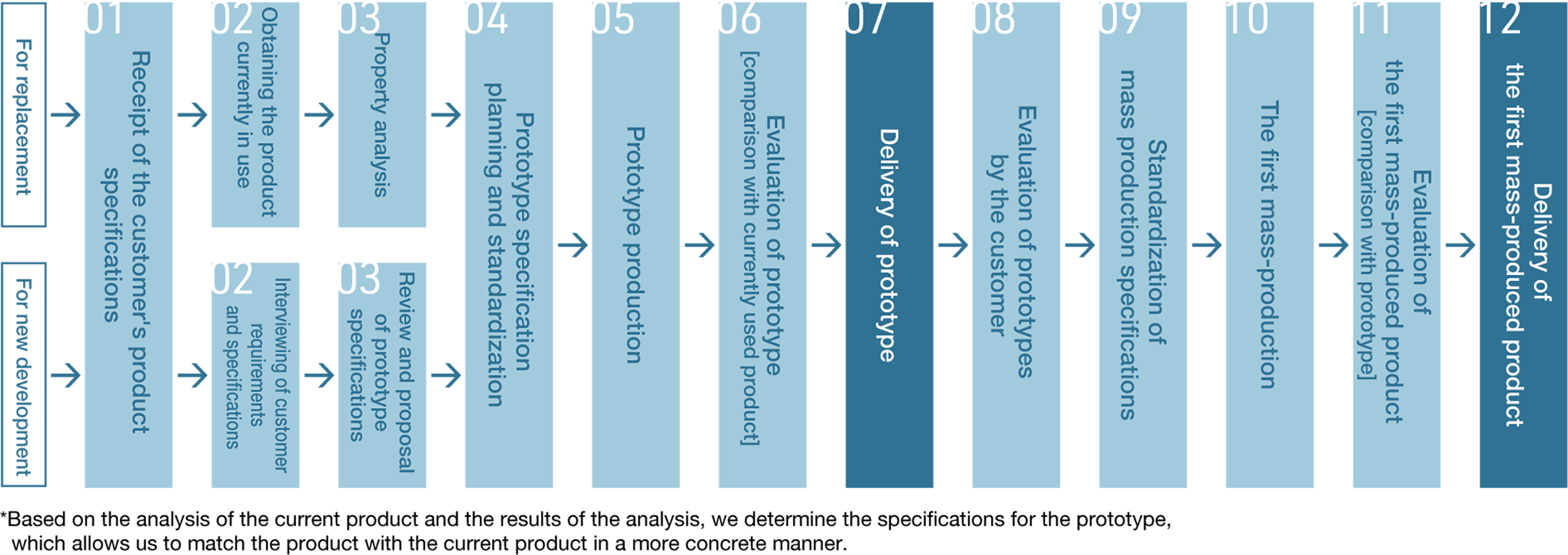

Quality Control Flow

[ Our inspection equipment ]

●Various dimensional measuring instruments : Made by MITUTOYO

●Image dimension measuring instrument : XM-1500 manufactured by KEYENCE

●3D Measuring Instrument : IM-7500 manufactured by KEYENCE

●Gauss meter : ML-20DH manufactured by MAGNET LABORATORIES

●Flux meter : DFM-1C manufactured by MAGNET LABORATORIES

●Demagnetizing device : PC-1510D manufactured by MAGNET LABORATORIES

●Other measuring and analysis equipment : Contract manufacturer's equipment

Solutions that Customers Can Trust

We diligently offer services ranging from prototypes to mass production and small-lot production, regardless of the type of magnet.

T.Technology's proven technical capabilities, ability to offer solutions, and high responsiveness will ensure a high level of customer satisfaction.

Efficient and precise mass production

[ Accuracy assurance of prototype ]

We will document the prototype specifications in our drawings and inspection standards. Based on our production instructions (drawings and inspection standards), we will request the Chinese contract manufacturer to manufacture and inspect the product. Upon our receipt, we will also inspect, evaluate, and analyze the product.

Please notify us of the following when making inquiries.

■Material name

■Purpose & use : Material, shape, dimensions, dimensional accuracy, appearance limits (drawings), and especially required finishing

■Use conditions : Assembly procedures, finishing procedures, and external forces, temperature, and other conditions influencing magnetic forces

■Inspection standards : Especially important characteristics and their inspection procedures

■Quantity required : Use quantity per month and use schedule in the future

■Other references : Purposes of inquiries (mass production, trial production, design changes, or the like), products currently in use, and their problems

■ Where to contact : Mr. Tsurumaki in charge of business TEL : +81-48-240-3030 E-mail : takashi@t-technology.co.jp